|

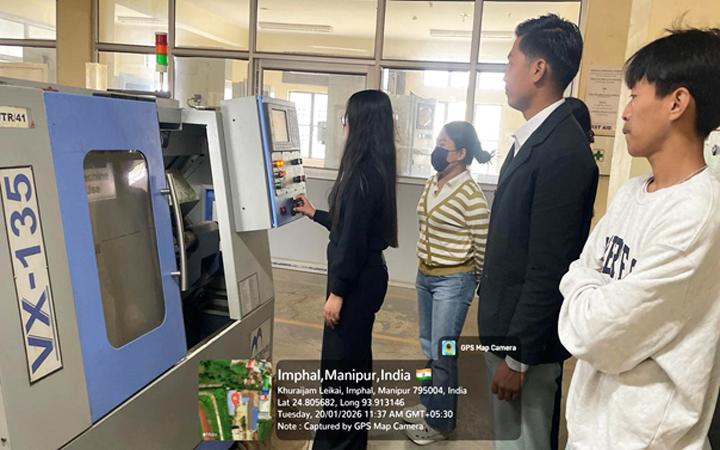

EVENT OVERVIEW – The Internship and Training Program on “Plastic Processing, CNC Milling and CNC Lathe” undertaken by MTU students at Central Institute of Petrochemicals Engineering & Technology aimed to provide industrial exposure and hands-on experience in modern manufacturing technologies. The program enhanced students’ technical competencies in plastic processing techniques and CNC machining operations, preparing them for industry-oriented careers. |

|||

|

Event Name |

Internship and Training Program on “Plastic Processing, CNC Milling and CNC Lathe” |

||

|

Event Date |

5th January 2026 to 24th January 2026 |

||

|

Event Description |

The 20-day internship program provided intensive practical training in plastic processing technologies such as injection molding and extrusion, along with CNC Milling and CNC Lathe machine operations. Students were trained in machine setup, tool selection, CNC programming basics, machining parameters, safety measures, and quality inspection procedures. The training emphasized real-time industrial practices and production techniques used in manufacturing industries |

||

|

Resource Person(s) |

Technical Experts and Trainers |

||

|

Coordinator(s) |

Dr. K Gopal Krishna Singh Assistant Professor, Mechanical Dept. , MTU |

||

|

Organized by |

Department of Mechanical Engineering, MTU In collaboration with |

||

|

Total Days of Event |

20 days |

||

|

The number of Students Participating in the program

|

MALE |

FEMALE |

TOTAL |

|

03 |

03 |

06 |

|

|

Number of Faculty & Staff who participated in the program

|

TEACHING |

NON-TEACHING |

TOTAL |

|

00 |

00 |

00 |

|

|

Number of Local participants |

MALE |

FEMALE |

TOTAL |

|

03 |

03 |

06 |

|

|

Location |

Central Institute of Petrochemicals Engineering & Technology (CIPET), IMPHAL |

||

|

Plan of action |

• Provide practical exposure in plastic processing and CNC machining. |

||

|

Action Report |

• Successfully completed 20 days internship at CIPET Imphal. |

||

|

Outcomes / Impact of the activity |

• Students gained real-time industrial exposure. |

||

|

Feedback |

· Participants highly appreciated the practical and industry-oriented training approach. · The CNC hands-on sessions were found to be extremely beneficial and insightful. · Participants suggested including advanced CNC programming modules in future internships. · Overall, the internship was informative, skill-enhancing, and career-oriented. |

||

Gallery :

Last Updated on February 20, 2026 by Web Admin